Dig Trenches Efficiently for Construction and Utility Projects

Dig trenches is a practical skill used for a variety of purposes, including installing utilities, drainage systems, and landscaping projects. It involves creating a long, narrow excavation in the ground, which requires planning and the right tools to ensure the job is done safely and efficiently.

To dig a trench effectively, one must understand soil types, use appropriate tools like trenching shovels or powered trenchers, and follow safety guidelines to prevent accidents or collapses. Whether done by hand or with machinery, proper technique and preparation are key to achieving a clean, stable trench.

Anyone looking to master trench digging should consider factors such as the trench’s depth, width, and purpose. These elements influence the methods and equipment used, making it important to tailor the approach to the specific project for best results.

Essential Steps for Digging Trenches

Successful trench digging requires precise preparation, the correct equipment, accurate layout, and careful excavation. Each step must be handled methodically to ensure safety, efficiency, and stability throughout the process.

Planning Your Trench

He should start by defining the trench’s purpose and dimensions, including length, width, and depth. This helps determine the type of soil and the complexity involved.

Before digging, checking for underground utilities is critical to avoid damage and hazards. Local utility companies or official marking services can provide this information.

He must also consider the soil type, slope, drainage, and environmental conditions. Planning includes allowances for safety features like shoring or benching if the trench is deep.

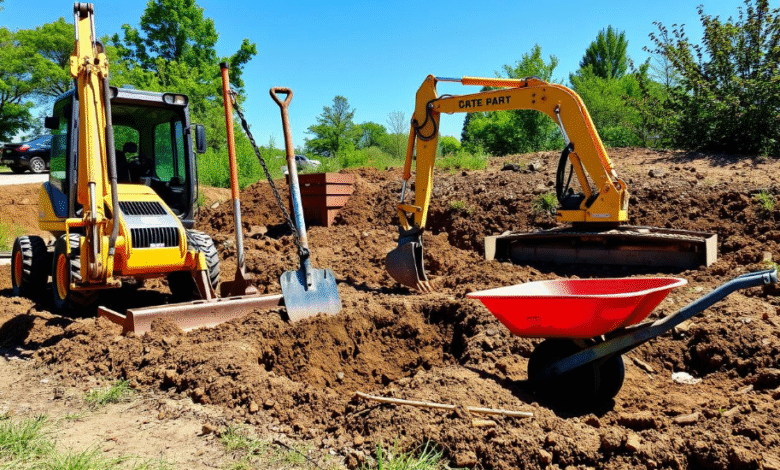

Gathering the Right Tools

Essential tools vary depending on trench size and soil hardness. Basic tools include a shovel for general digging, a spade for cutting through compact soil, and a mattock for breaking hard ground.

For deeper or longer trenches, additional equipment like wheelbarrows, measuring tapes, and stakes improves efficiency. Personal protective equipment—helmets, gloves, and boots—is necessary for safety.

Hand tools suit small or narrow trenches, while larger projects may require mechanized trenchers or excavators for speed and precision.

See also: Understanding The Importance Of Life Insurance In Financial Planning

Marking and Measuring the Trench Path

Accurate marking ensures the trench follows the planned route without errors. Stakes or spray paint can outline the trench boundaries visibly.

He must measure regularly to maintain the correct width and depth, using tape measures or laser levels. This prevents unnecessary rework or misalignment.

Maintaining a straight line or correct curvature depends on project requirements. Precise marking reduces the risk of structural problems or drainage issues later.

Executing Safe and Efficient Digging

Digging should proceed incrementally, removing soil in layers to prevent trench collapse. For trenches deeper than 1.5 meters, protective measures like shoring or benching are required to stabilize the walls.

He should avoid digging too deep in one pass and instead take multiple passes to keep the trench stable. Keeping the trench bottom even aids in proper drainage.

Efficient digging also involves proper soil disposal away from trench edges to avoid additional pressure on the walls. Regular inspection during excavation ensures safety and adherence to plans.

Best Practices and Safety Considerations

Proper planning and careful execution are essential for safe trenching operations. This includes maintaining trench stability, managing soil and debris effectively, and ensuring proper water drainage to prevent hazards.

Trench Stability and Support

Trench walls must be supported to prevent cave-ins, one of the leading causes of trenching accidents. Protective systems, such as shoring, shielding, or sloping, should be used based on soil type and trench depth.

Soil classification is critical in selecting the appropriate support system. Cohesive soils may require different protection methods than loose or sandy soils. Trenches deeper than 5 feet require protective measures unless the excavation is in stable rock.

Regular inspections by competent personnel are necessary, especially after weather changes or vibrations from nearby equipment. Workers should never enter unsupported trenches deeper than 5 feet.

Managing Soil and Debris

Soil and debris should be placed at least 2 feet away from trench edges to avoid additional pressure that can cause collapses. This setback reduces the risk of soil displacement into the excavation.

Properly organized spoil piles also help maintain clear access and exit routes. Pathways should be free of obstructions to prevent slips, trips, and falls.

Heavy equipment should operate at a safe distance from trench edges to minimize soil disturbance. Managing materials in an orderly manner improves site safety and worker efficiency.

Water Drainage Solutions

Water accumulation in trenches increases the risk of collapse and creates unsafe working conditions. Effective drainage systems, such as pumps or trench drains, should be installed to keep the area dry.

Operators should monitor weather forecasts and be prepared for heavy rain events. Temporary barriers or berms can help divert surface water away from the excavation site.

Water removal devices must comply with safety standards and be regularly inspected to ensure proper function. Draining water promptly reduces soil destabilization and maintains a safer work environment.